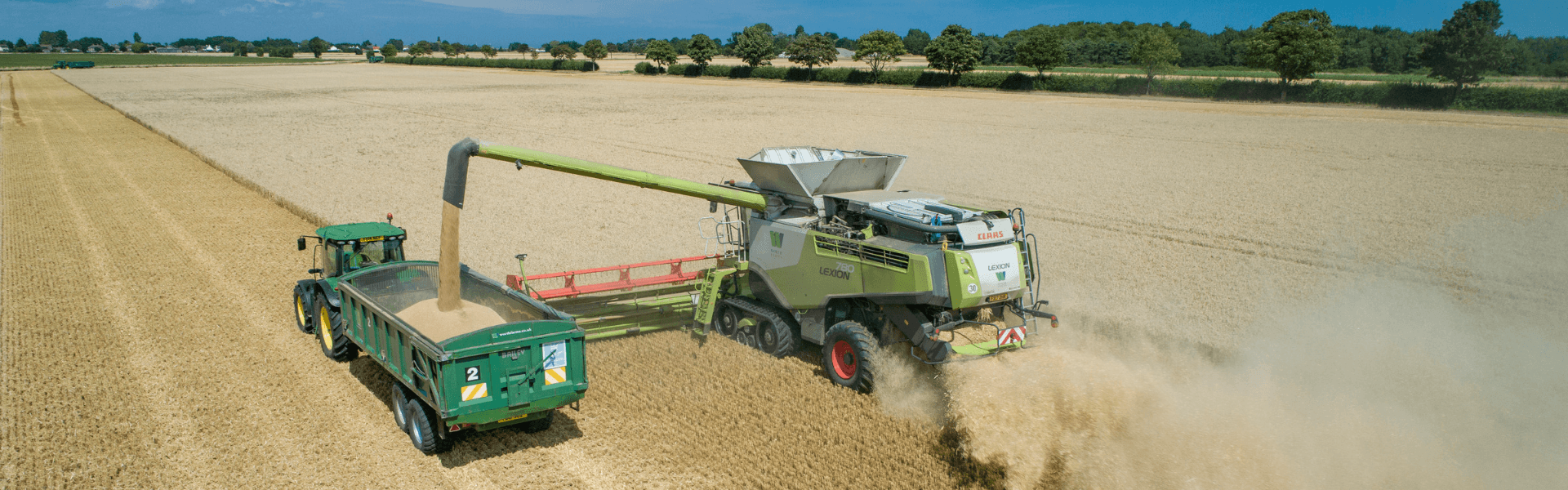

Best in Field Harvest 2022 - Winter Wheat

ROSS DAWSON

Congratulations to Simon Day of Worth Farms, credited with the lowest cost of production for Winter Wheat at £33.08 per tonne. Ross Dawson sat down with Simon to learn more about their impressive farming operation and plans for this and next season.

Simon, tell us a little about yourself:

I've been at Worth Farms for 13 years now, 8 of which have been as the Farm Manager. Before that, I was at Velcourt as an assistant manager on a local farm here in South Lincolnshire. I am originally from North Lincolnshire where my family farm. I am also FACTS and BASIS qualified.

Tell us about the farm:

Worth Farms is approximately 3000ha of owned, rented and contract farmland in the Holbeach Marsh area in South Lincolnshire, with a team of 12 long-serving staff. The land is all Grade 1 silt on which we grow Winter and Spring Wheat, Sugar Beet, Potatoes, Vining Peas, Forage Maize and Mustard with land let out for specialist vegetable and salad crops. We're lucky with this silty land as it is naturally moisture-retentive which suits growing high-yielding feed wheat.

Your wheat cost of production for 2022 were at an impressive £33.08/tonne, considering the rising costs and inflation. Can you tell us more about what you do and what you consider when growing wheat?

All our wheats this year are feed varieties. We look for the best-yielding varieties on the AHDB Recommended list to see what’s worth growing. We are lucky in that we don't have a lot of blackgrass on the farm, so we are able to drill early. Last year, we drilled about 25% in September, 50% In October, and then 25% in November / December.

Fertiliser wise we use liquid fertiliser in two splits starting early March, and then early April. All the land around the main farm has digestate applied as we've got an on-site AD plant giving us digestate as a by-product. That is applied at approx. 60 cubic meters/hectare, giving us around 110 kilos of nitrogen, plus about 100 kilos of phosphorus and 400 kilos of potassium with sulphur, magnesium, etc as well; so, it's given a good chunk of nutrients allowing us to reduce the bagged synthetic fertiliser for the wheat. For subsequent potato & sugar beet crops, we also cut back on the P and K that we need to put on. So, we are fortunate to be massively reducing the fertiliser we're buying. We recently trialled a couple of fields with only digestate applications which both performed well.

Will you be doing more of that, or do you think there's always going to be a need for ‘bought-in synthetic fertiliser’ within your system?

I think there's always going to be some synthetic. Its dependant on location and ease of spreading. We have an underground irrigation main which we use to pump the digestate round. It takes a lot of pumping over long distances, so we can't reach the outlying fields, and getting tankers in to take it around to those fields isn’t cost-effective.

We touched on it a little bit with the use of your own digestate, what are you doing to combat the rising input costs and uncertainty?

Yes, the use of our digestate is a big one, looking at different varieties is also key. Growing cleaner, better agronomically scoring varieties from the AHDB Recommended list with the best output for us as a business. We have looked at growing quality wheats in the past, but they can cost significantly more to grow due to disease pressure or yield penalties, so if we can grow feed varieties at an efficient price whilst getting a larger output then that makes more sense for us. On top of this, we are trying to use more generic products and cheaper chemistry, where possible.

And how often would you say you're changing varieties? Or would you tend to stick with a certain number that work for the farm for longer periods of time.

Last year we had some Parkin, Gleam, Graham and SY Insitor. We used to grow quite a lot of KWS Grafton, which is what we were growing when we won the Best in Field before (back in 2020). That was getting a bit outdated, and I think Parkin has come along and superseded that, we use it for early drilling because it has good standing ability on this fertile silty soil. We can drill it in early/mid-September, and we know it’s not going to fall over!

The Gleam and Graham have achieved a positive, reliable yield and the SY Insitor we use for the late drilling slot in November/December following sugar beet and veg. Going forward, we’ll have our 5 core varieties, trialling any potential replacements in a couple of fields.

In terms of your crop sales strategy, are you selling forward periodically, or do you tend to wait and take advice on prices?

We’re always looking ahead. We probably put around 25% of our wheat in a grain pool, which is marketed through Openfield. Going forward, we're probably going to up that to 30 or 40%. The balance we sell ourselves with pricing advice from Openfield. We started selling harvest 2022 crop in March 21 for £161/t, which was a good price at the time! We tend to sell in 5% chunks throughout the season, which helps with budgeting, and some of the later sales ended up at £320/t. So, we're probably going to average about £250/t for this crop (2022). We're going to end up better than budgeted with that price on top of the yields we've had this year which themselves were 1800 tonnes above budget! We still have about 900 tonnes of wheat left to sell, which we hope will be around the £230/t mark.

What has made you decide to put more crop into the grain pools next year?

Risk management; I think the guys that are selling the grain in the pools have got a lot more information and are watching the markets all the time. Normally, the pool price and our sales price have almost aligned, but in years when the market is more volatile, the pool more effectivly manages the price risk. So, my logic is to put a bigger percentage into pools whilst the volatility remains high.

You mention Risk Management, how do you think you could use your YAGRO platform more to inform your future decision making on farm and help to mitigate risk?

I think using Tracker more to see where our costs are against budget and against where we were last year is something we need to spend the time looking at. Analysing fields to see which ones are performing and comparing varieties to see what we’re spending on each and what they yield to better inform our variety choices for the future.

So, plans for next year, are you are you planning to do anything differently? Any new technologies, new machinery, or other plans?

We've kept quite a few of the varieties for 2023, this year we've kept Parkin, Gleam, Graham and SY Insitor and introduced KWS Dawsum. We’ll be growing some spring wheat on a block of land that is coming out of maize production.

Where we've done three applications of nitrogen in the past, we're going to do it all in two applications this year with a larger application early on, we’ve seen that getting the nitrogen on early leads to the best results. So, we’ll start spreading this week; with the soil conditions as good as they are we need to make the most of it.

Establishment-wise, we've invested in a second drill. We have our 8-meter Vaderstadt drill that we would normally do the bulk of the work, but now we also have a Lemken 6 metre combination drill that we will utilise more when the conditions are too wet to go through with the Vaderstadt. The Lemken combination drill is a really good piece of kit and will allow us to keep going and get that seed in the ground, it has also allowed us to shuffle our tractors around a bit and move from huge, tracked machines to wheeled tractors with better capacity and economies.

We purchased a bowser so that our sprayer operator can reduce the amount of time spent going back and forth to the yard to re-fill, that makes the sprayer and the operator's time more efficient and when there is a short spray timing window need to be out there.

And finally, what would you say are your top three considerations when growing wheat? i.e. if you get 3 things right, you’re on track for a good crop.

Firstly, drilling conditions, getting it drilled at the right time into good soil is the first step. The Second would be early nutrition, applying nutrition early to give the crop all the nutrients it needs, and then thirdly, lots of sunshine in May and June!! I know we can’t control that one but the more sunshine we get, the bigger the potential, so we need to make sure we’re setting the crop up, getting it drilled properly, giving it the nutrition to get the big yield at the end!

Congratulations to Simon and the team at Worth Farms for their epic production and being YAGROs Best in Field Winter Wheat 2022.