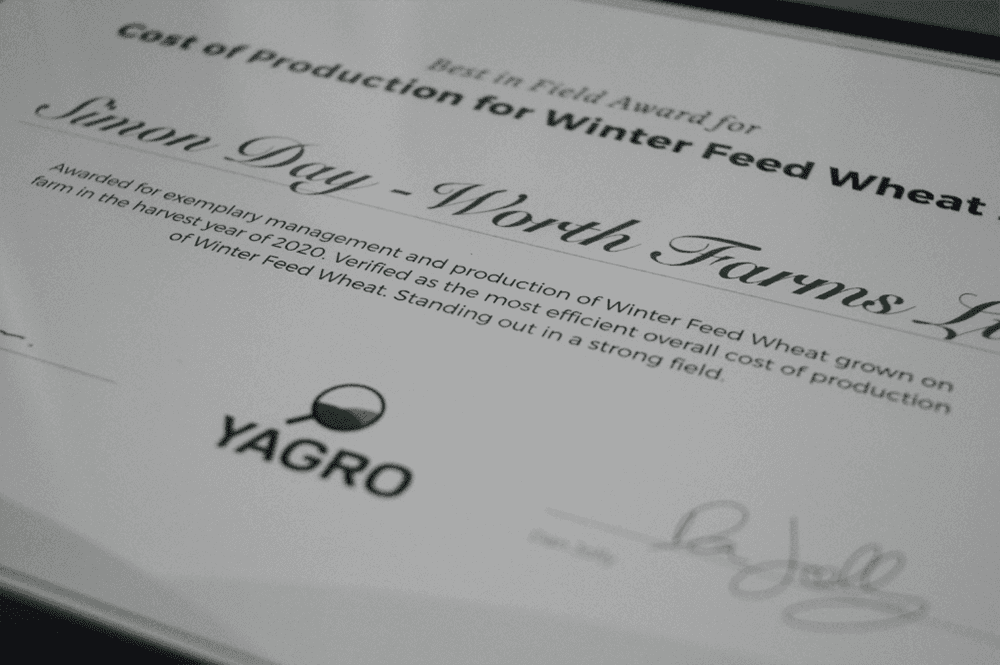

Lincolnshire Farm has the best Cost of Production for Winter Feed Wheat

RUPERT HARLOW

Worth Farms in Lincolnshire have been identified as the Best in Field for Winter Feed Wheat producing KWS Grafton at £29.91 per tonne, meaning they had the most efficient overall cost of production for Winter Feed Wheat in 2020. Simon Day is the Farm Manager of the 2,500ha farm; we sat down with him to find out more about how they achieved this and their future plans.

Tell us about yourself.

I've been at Worth Farms for 11 years now, 6 of which have been as the Farm Manager. Before that, I was at Velcourt as an assistant manager on a local farm here in South Lincolnshire. My parents farm in North Lincolnshire. I am also FACTS and BASIS qualified.

Tell us about the farm:

Worth Farms is 2,500ha of rented and contract farmland in Lincolnshire with a team of 12 long-serving staff. The land is Grade 1 silt across the board on which we grow Winter Wheat, Sugar Beet, Potato, Vining Peas, Leeks, Forage Maize, Forage Rye and Spring Barley. We're lucky with this silt land as it is naturally moisture-retentive, even in a drought, which is fairly typical of this area, and high yielding feed wheat are what we're good at! We have a fully integrated supply chain with our Potatoes from growing through to them arriving on the supermarket shelves.

Tell us some more about your Winter Feed Wheat:

We've grown the Grafton for several years now and like it because you can drill it in early September and harvest it early the following August. It's short strawed, so it stands well on these fertile silts, and it won't fall over. That's part of the reason why it has come out reasonably strong this year despite the high winds and rain in early August. Lots of grain ended up on the floor with our other varieties. But with Grafton, we cut it when the bushel weight was still high and got that quality and quantity, which led to it being our highest yielding wheat.Our average yield on Grafton was 11.2t/ha last year, with some parts of the farm yielding as high as 13t/ha, which gave us the weighted average cost of production you’ve shown of £29.91/t, with fields ranging from £23.27/t through to £43.38/t. Our yield was hugely affected by the weather. We managed to get the 146ha of Grafton in with a Vaderstad 8m drill before the weather turned, then from mid-October to March, we drilled the remaining 730ha with a 4m combination drill. The flooding had a significant impact on our yields, with around 15-20ha of headland area that we simply couldn’t drill with wheat, so we ended up putting cover crop on those areas and planting in the Spring when things had dried out.The Farm2500ha in LincolnshireGrade 1 silt soilCrops grown; Winter Wheat, Sugar Beet, Potato, Vining Peas, Leeks, Forage Maize, Forage Rye and Spring BarleyAD Plant on farm

We had to do a lot of planning and jiggling around of the rotation. We knew we wouldn’t be able to establish Winter Wheat in some fields in the Autumn, so we switched those to a Spring drilling crop like Maize and vice versa. In the end, we managed to drill pretty much 100% of the area we wanted to, albeit some in different fields, so it was a great achievement by the whole team, and it was definitely the right thing to do.

I take it you won’t be dropping Grafton as one of your varieties any time soon?Well, getting seed has become the issue, so we haven't actually got any Grafton in the ground this year. For harvest 2021, we've moved to KWS Parkin which is seen as the Grafton replacement for that early drilling slot, so we are hoping for even higher yields. We started drilling on 14th September and what is in the ground looks fantastic so far!

We did toy with the idea of home saving seed for Grafton but decided it had had its day and was becoming less sought after.

Going back to the weather, do you see this weather change as becoming the new normal and are you changing your plans to adapt to it?

Rainfall is definitely on the increase; the last five years have seen an average rainfall of 708ml a year. We are looking at our rotation carefully and the viability of certain crops, such as Sugar Beet, which due to its cost of production and the soil conditions following the late lifted crop, going forwards it may no longer work for us.

We’re also looking at machinery to help improve soil structures, we've run tracked machines for a long time, and we're reducing the amount of ploughing we're doing as well. In the past, we've ploughed two-thirds of the farm each year, whereas now, we're ploughing less than a quarter. We're moving from two 400hp CAT Challengers to one 9RX John Deere 600hp, which we are going to buy a 6.5m Sumo Trio with a good seeder to help establish good cover crops.

Your seed cost for Winter Wheat is very low; how do you achieve this?

We drilled Grafton early at around 180 seeds per m2 which worked out at about 140kg/ha (YAGRO Analytics median of 150kg/ha), so our seed rate itself is very low, which means we don't need to buy a huge amount of it. We purchased the seed at a good price, we have a number of tenders that we get quotes for seed from, and then we buy from the cheapest; last year, we paid £354/t for Grafton from GFP; this year, we bought it from Openfield. We're also fortunate that we're not in a black-grass area, so we don't have that pressure."We're not aiming to hit the top of the market and beat Joe Bloggs next door; we're looking to beat our own budget and sell on the way up rather than on the way down."

Looking at your Analytics platform, both your fertiliser and chemical application rates are at the lower end. Can you shed some more light on that?

Our low fertiliser spend is all to do with digestate; we have an AD plant on the farm run by BioGen. We grow some Feed Maize for that, on the agreement that we get the digestate back free of charge, which probably saves us between £70-100,000 a year. On fields where we applied 230kg of nitrogen, 127kg of that came from digestate, so it’s a huge saver. On our best field, this allowed us to apply only 92.5kg/ha of Chafer Nuram 37 liquid fertiliser. On the chemical side of things, black grass isn't really an issue for us; our main concern is weeds like groundsel. We let out 250ha a year for salad production, and they struggle to control the groundsel as they don't have the chemistry, so we can get a build-up of groundsel to sort out. Apart from that, we spray a Strarane /Ally Max mix to clear up any weeds that have come through in the Spring, so it's all pretty straightforward.

We buy all our pesticide from Agrii, and this will be our third year of benchmarking and rebating with them, thanks to Dan and the team at YAGRO. We send them an itemised spreadsheet of where we feel prices should be with your YAGRO data and negotiate a rebate with those figures.

Your fungicide spend across the board is much higher than we would expect. You’re applying Epoxiconazole at 94g/ha compared to the median of 73g/ha, Tebuconazole at 361g/ha compared to 205g/ha and Prothioconazole at 200g/ha compared to 140g/ha. What’s causing the high applications?

Being so close to The Wash puts us in this disease hotspot; we get the sea mists, and it's damp. Septoria is a big issue for us, and we would judge application on potential; The early wheat had a strong application because, at the time, we thought there was a significant risk there. On other crops that were late and thin, we scaled back on the inputs as the risk was much lesser.

Who does the Agronomy on farm?

We have John Youles from TAG, he does a lot of agronomy in the area, and he's a really good guy to have as a custodian of the farm. John provides the advice, and then we sit down and work out a plan of what we're going to do; then, I buy the chemicals from Agrii. We keep the advice and the chemical supply separate.

You mentioned working on a crop's potential. How do you budget for a year?

We sell forwards a percentage of the crop. We do a cost of production model in house, which includes everything, even overheads, so it is a full budget. We set the budget and put those figures into our model, and if we can see the price going ahead of our budget, we'll look into it. We’re not aiming to hit the top of the market and beat Joe Bloggs next door; we're looking to beat our own budget and sell on the way up rather than on the way down.

We then review that budget midway through the season, and then we'll do our cost of production at the end of the year.

We keep track of the cost of production, what we’re spending and where we’re selling. That’s why I'm interested in moving forward with YAGRO and their Analytics package to keep track of that. "We have a fully integrated supply chain with our Potatoes from growing through to them arriving on the supermarket shelves."

Looking forward to this season, you mentioned Grafton is out; what's gone in the ground?

This year we planned for KWS Parkin, Gleam, Graham, KWS Extase and KWS Firefly; then, I had to buy some extra seed in late on because of drilling conditions and seed rates. Some land then became available, so we bought LG Spotlight and KWS Crispin, which were available at the time.

Switching to BPS and subsidies, what impact will that have when they go?

They’re a big part of our profit, though we will still be profitable without them. We’re going into a Countryside Stewardship Scheme too to offset some of that; the business is quite environmentally focussed. I’ve looked at the scheme, and we're several small fields out of production, so anything under 2ha will go into the stewardship scheme. We're a tenanted farm business, so we pay rent on every acre we farm. We’re looking at what can be done in all areas to improve efficiency, right down to the last pound per ton to reduce costs. You could argue that this Grade 1 silt should be farmed wall to wall with crops because they yield so well, and that's how we could earn our money, but we are looking to farming efficiently. Machinery is a big one, and the large equipment does about 8-10 years, but we're stretching that where we can. We run one sprayer, which gets changed every five years; we’re making efforts to look after our machinery better, and also sharing to reduce costs.

In terms of credit where it's due, you've mentioned your agronomist and yourself in terms of managing it. Who else do you credit with helping win this award?

The team on the ground deserve credit as well; they're the guys doing the work to establish and combine it. They're in the fields, and if they don't drill it right and if questions aren’t asked about what went wrong, we won’t improve. There is always space to find efficiencies and improvements in what we do.

Congratulations to Simon Day and the team at Worth Farms for winning our Best in Field Award for having the best cost of production for Winter Feed Wheat!